Wood paneling has made a remarkable comeback in home interior design, offering a blend of warmth, texture, and sophistication to any space. Whether you're looking to create a cozy atmosphere in your living room or add a touch of rustic charm to your bedroom, home interior wood paneling can be the perfect solution. This comprehensive guide will walk you through the process of selecting the ideal wood paneling for your home, ensuring that you make an informed decision that aligns with your style preferences and practical needs.

Understanding Different Types of Wood Paneling

Before delving into the selection process, it's crucial to familiarize yourself with the various types of wood paneling available in the market. Each type has its unique characteristics, advantages, and potential drawbacks.

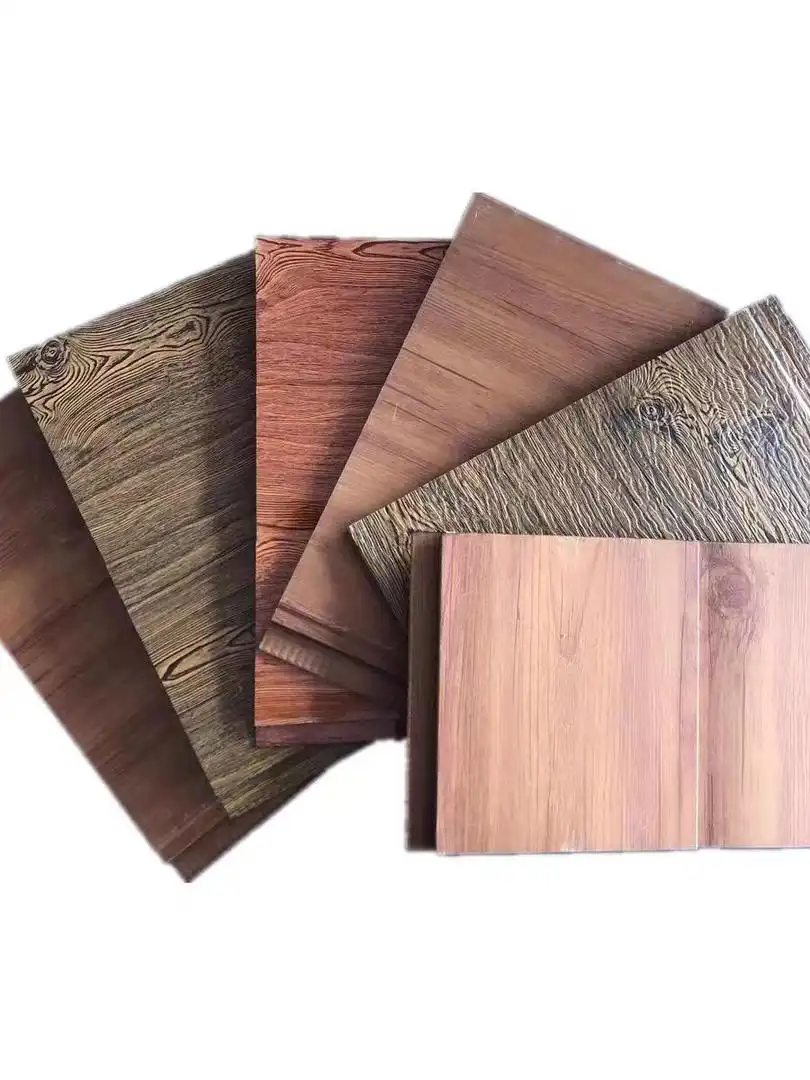

- Solid Wood Paneling: As the name suggests, this type of paneling is made from solid pieces of wood. It's known for its durability and authentic appearance. Popular wood species for solid paneling include oak, pine, cedar, and walnut. Solid wood paneling can be quite expensive, but it offers unparalleled natural beauty and can last for generations with proper care.

- Engineered Wood Paneling: This option consists of a thin layer of real wood veneer applied to a plywood or medium-density fiberboard (MDF) backing. Engineered wood paneling provides the look of solid wood at a more affordable price point. It's also less prone to warping or shrinking due to changes in humidity, making it a practical choice for many homeowners.

- Reclaimed Wood Paneling: For those seeking an eco-friendly option with character, reclaimed home interior wood paneling is an excellent choice. This type of paneling is made from wood salvaged from old buildings, barns, or other structures. Each piece tells a story and brings a unique, weathered charm to your interior spaces.

- Peel-and-Stick Wood Paneling: This modern option offers a convenient and DIY-friendly way to incorporate wood paneling into your home. These panels come with an adhesive backing, allowing for easy installation without the need for nails or glue. While they may not have the same longevity as traditional wood paneling, they're perfect for renters or those looking for a quick and reversible upgrade.

Factors to Consider When Choosing Wood Paneling

Selecting the right wood paneling for your home involves more than just picking a style you like. Several factors should influence your decision to ensure that the paneling not only looks great but also performs well in your specific environment.

- Room Function and Atmosphere: Consider the purpose of the room where you plan to install the wood paneling. A formal dining room might benefit from elegant, dark wood paneling, while a casual family room could be better suited to lighter, more rustic options. Think about the atmosphere you want to create and choose paneling that complements this vision.

- Existing Décor and Color Scheme: Your home interior wood paneling should harmonize with your existing furniture, flooring, and color palette. If you have predominantly cool tones in your space, consider warmer wood tones to create balance. Conversely, if your décor features warm colors, cooler wood tones can provide a pleasing contrast.

- Natural Light: The amount of natural light in a room can significantly impact how wood paneling appears. Darker woods can make a room feel cozy but may also make it seem smaller and darker. In rooms with limited natural light, lighter wood tones can help brighten the space and create an illusion of more room.

- Maintenance Requirements: Different types of wood paneling have varying maintenance needs. Solid wood may require periodic refinishing to maintain its appearance, while engineered options might be more low-maintenance. Consider your willingness and ability to care for the paneling over time.

- Moisture Resistance: If you're planning to install wood paneling in areas prone to moisture, such as bathrooms or basements, opt for wood species or engineered products that are naturally resistant to moisture or have been treated for enhanced durability in damp environments.

- Budget: Wood paneling can vary significantly in price. Establish a budget early in the process and explore options that fit within your financial constraints. Remember to factor in not just the cost of materials but also installation expenses if you're not planning a DIY project.

Innovative Ways to Incorporate Wood Paneling in Your Home

Wood paneling offers versatile design possibilities that extend beyond traditional full-wall applications. Here are some creative ways to incorporate wood paneling into your home's interior:

- Accent Walls: Instead of paneling an entire room, create a focal point by applying wood paneling to a single wall. This can add depth and character to a space without overwhelming it. An accent wall can be particularly effective in bedrooms, living rooms, or home offices.

- Ceiling Applications: For a unique twist, consider installing home interior wood paneling on your ceiling. This unexpected application can add warmth and visual interest to a room, especially in spaces with high ceilings. It's an excellent way to make a bold design statement without altering your wall space.

- Wainscoting: Partial wall paneling, or wainscoting, is a classic way to incorporate wood into your interior design. Typically installed up to chair-rail height, wainscoting can protect walls from scuffs and marks while adding architectural interest to dining rooms, hallways, or living areas.

- Built-In Furniture Accents: Integrate wood paneling into built-in bookshelves, entertainment centers, or headboards for a custom, high-end look. This application can create a seamless transition between your furniture and walls, enhancing the overall cohesiveness of your space.

- Kitchen Island Cladding: Give your kitchen island a makeover by cladding its sides with wood paneling. This can add warmth and texture to what might otherwise be a plain or utilitarian element in your kitchen.

- Sliding Doors: Replace traditional closet or room divider doors with sliding panels made from wood. This not only serves a functional purpose but also becomes a striking design feature in your home.

- Bathroom Vanity Backsplash: In lieu of tile, consider using water-resistant home interior wood paneling as a backsplash behind your bathroom vanity. This unexpected application can add a spa-like feel to your bathroom design.

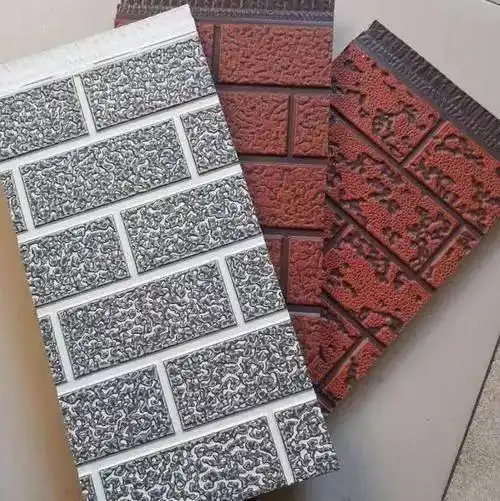

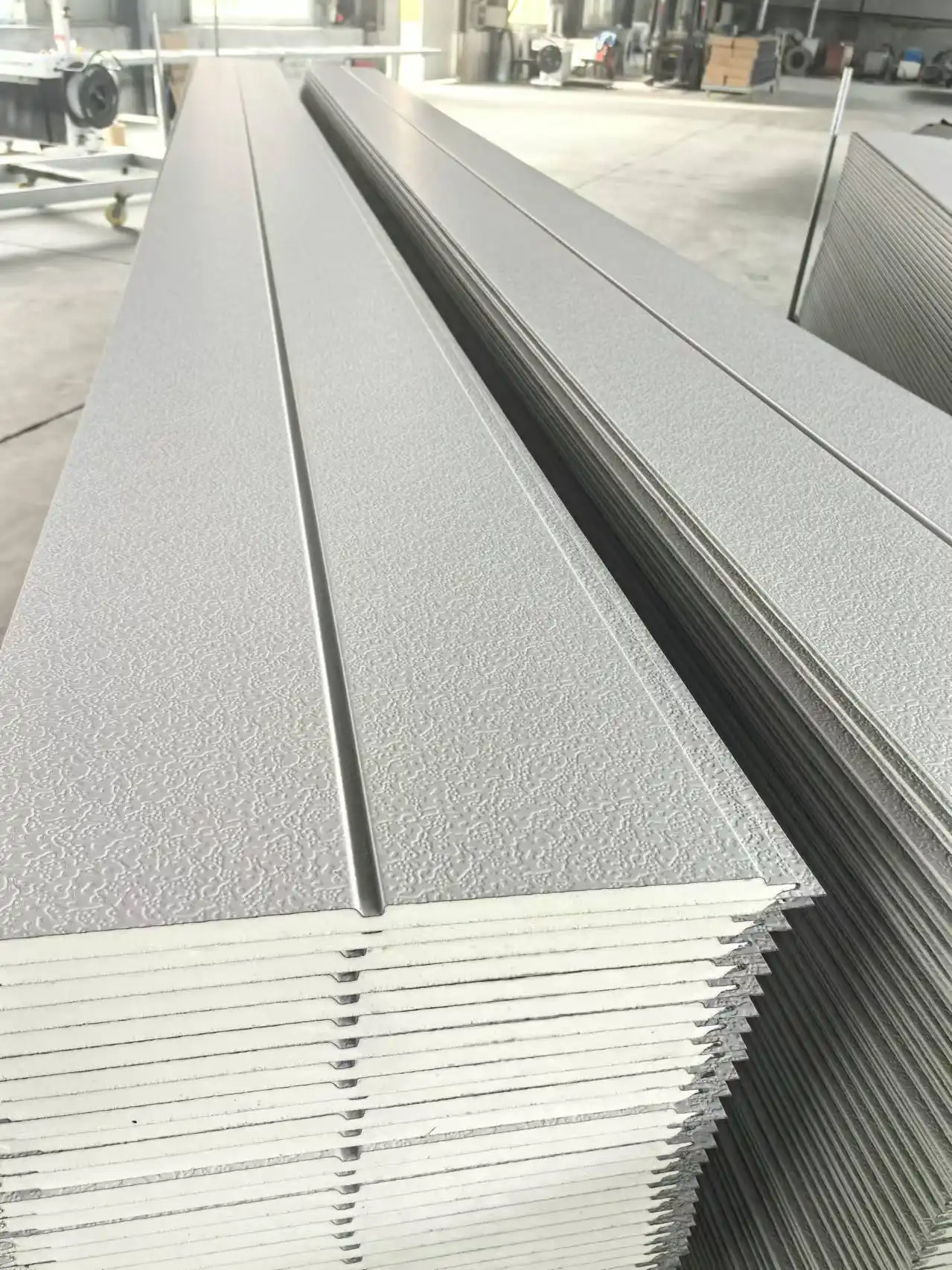

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right materials for your home improvement projects. While our expertise lies in exterior cladding and facade solutions, we recognize the value of home interior wood paneling in creating beautiful, functional living spaces. Our commitment to quality and innovation in building materials extends to all aspects of construction and design.

Conclusion

While Weifang Sandong Building Materials Co., Ltd. specializes in exterior solutions, we're always excited to see how our customers integrate various materials to create cohesive designs that flow from the outside in. If you're looking to complement your interior wood paneling with high-quality exterior cladding or facade solutions, we invite you to explore our range of products.

For more information on exterior cladding and facade solutions that can enhance the overall aesthetic of your home, please don't hesitate to contact us at info@sdqsc.com. Our team is dedicated to providing unparalleled service and products to elevate your building projects, whether you're focusing on interior improvements or exterior enhancements.

In conclusion, choosing the right wood paneling for your home is a journey of discovery – one that allows you to express your personal style while adding value and beauty to your living spaces. With careful consideration and creative thinking, you can use home interior wood paneling to create interiors that are not just visually appealing but also uniquely yours.

References

1. Wood Handbook - Wood as an Engineering Material. Forest Products Laboratory. United States Department of Agriculture Forest Service. Madison, Wisconsin. 2010.

2. Interior Design Materials and Specifications. Lisa Godsey. Fairchild Books. 3rd Edition. 2021.

3. The Encyclopedia of Wood. U.S. Department of Agriculture. Skyhorse. 2007.

4. Understanding Wood: A Craftsman's Guide to Wood Technology. R. Bruce Hoadley. The Taunton Press. 2000.

5. Architectural Woodwork Standards. Architectural Woodwork Institute. 2nd Edition. 2014.

.webp)

.webp)

.webp)

de

de