- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

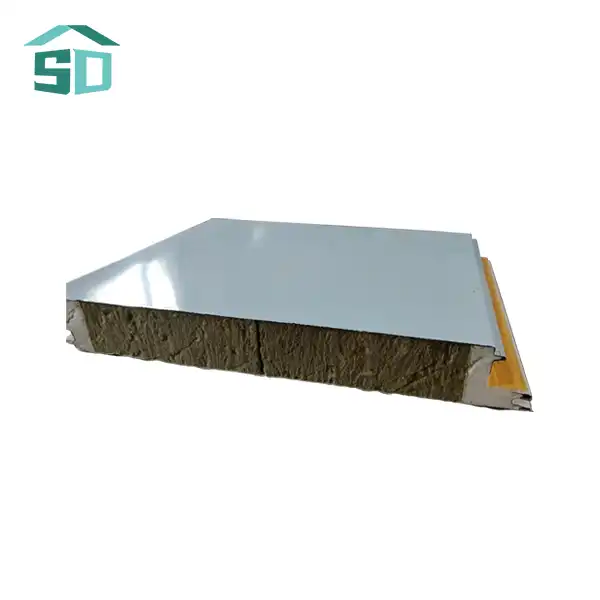

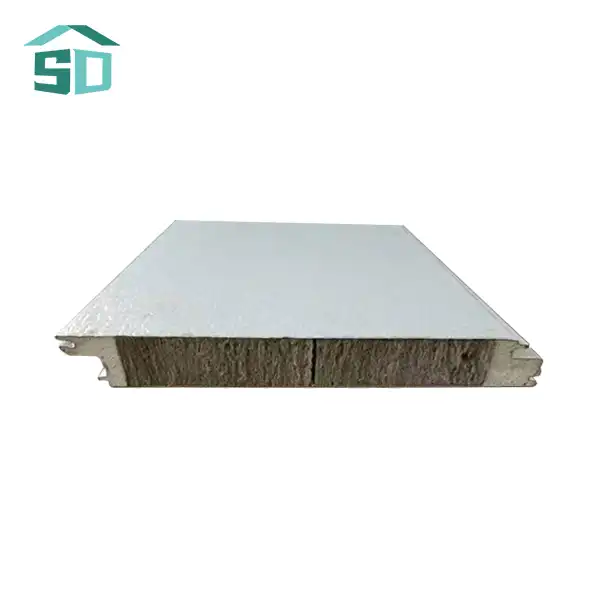

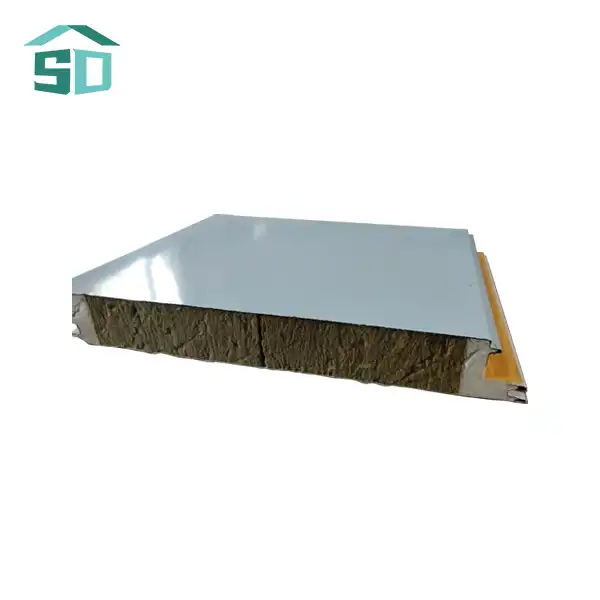

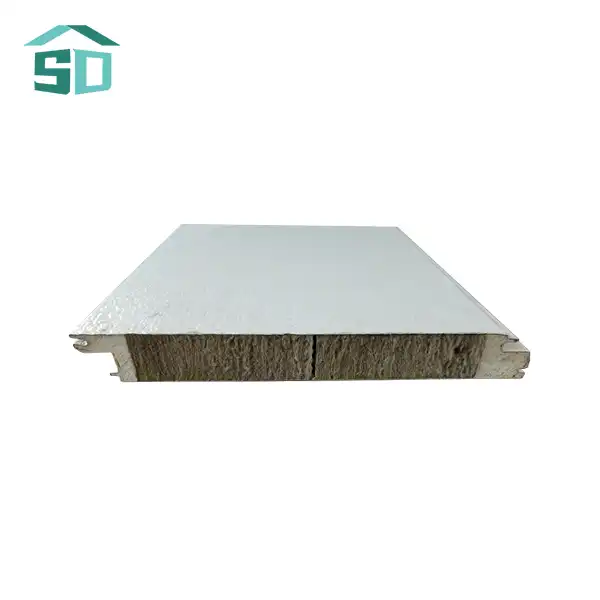

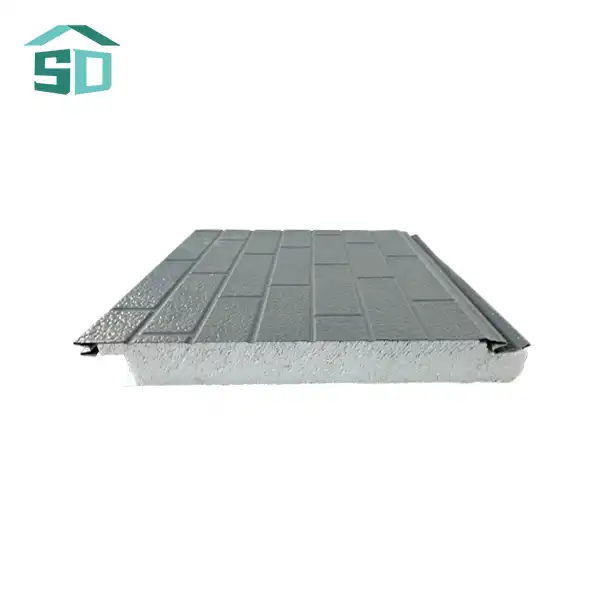

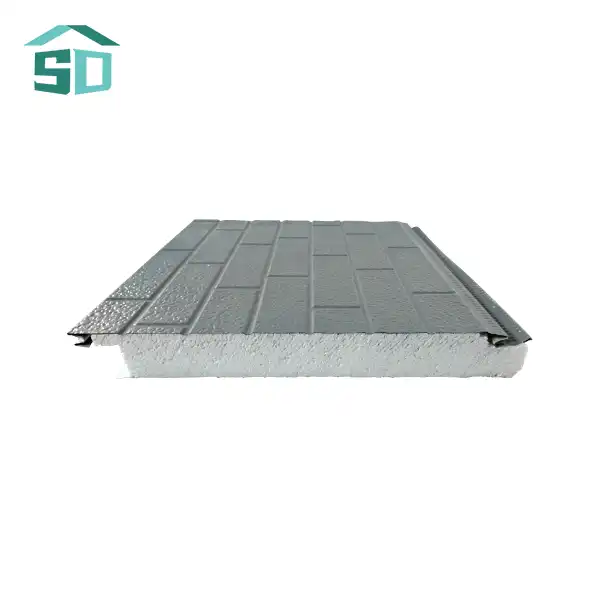

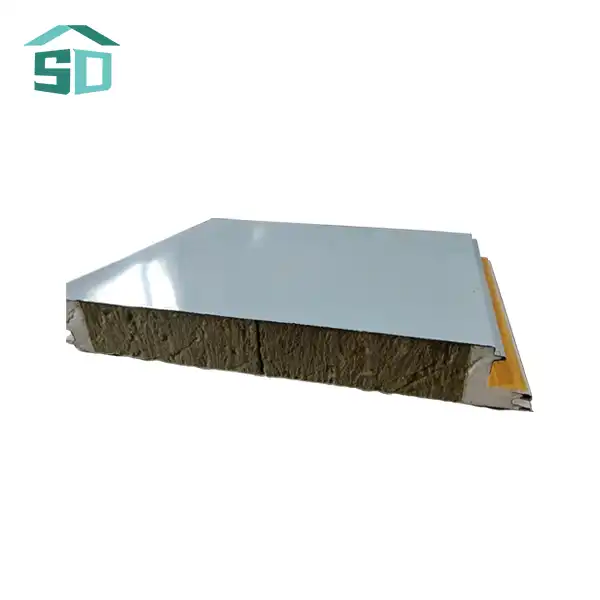

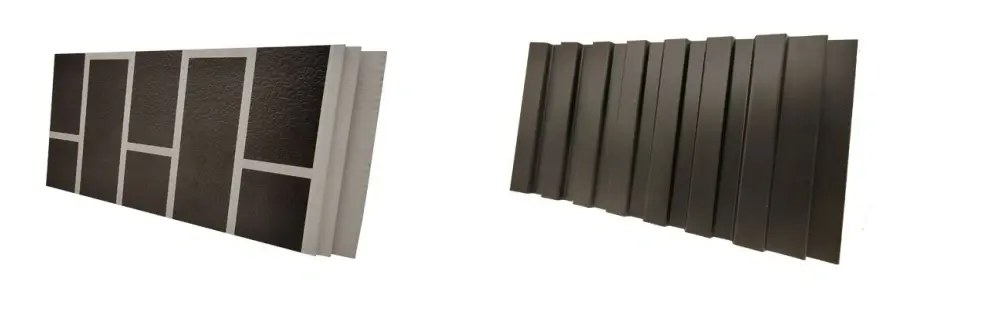

Insulation board

Insulation board is an effective solution for enhancing energy efficiency in both residential and commercial buildings. With outstanding insulating properties and excellent value, they can be used in various areas, such as roofs, floors, and walls, to improve thermal performance in a cost-effective and eco-friendly way.

As one of the leading insulation board manufacturers and suppliers in China, we warmly welcome you to wholesale insulation board for sale here from our factory. Contact us for sample!

Insulation Boards

Sandong Building Materials focuses on the production and research and development of insulation boards, and is committed to providing innovative and efficient insulation solutions for the fields of construction, industry and environmental protection. Sandong Building Materials adheres to the concept of sustainable development, always adheres to the principles of environmental protection and energy conservation, and is committed to providing customers with the highest quality insulation boards and the most professional services.

Introduction

Insulation boards are materials used to improve the thermal efficiency of buildings or industrial equipment. They mainly achieve thermal insulation by reducing heat conduction, radiation or convection. Insulation boards are usually made of high-performance thermal insulation materials and have excellent thermal isolation properties. They can effectively reduce energy loss and improve the energy efficiency of buildings. Insulation boards are widely used in walls, roofs, floors, pipes and other parts.

Specification

|

Material Type |

Thickness Range (mm) |

Compressive Strength (kPa) |

Dimensions (mm) |

Fire Rating |

|

Extruded Polystyrene (XPS) |

20 - 200 |

200 - 500 |

1200 x 2400 |

B1 (Flame Retardant) |

|

Polyurethane (PUR) |

20 - 100 |

150 - 400 |

1200 x 2400 |

B1 (Flame Retardant) |

|

Rock Wool |

50 - 100 |

80 - 250 |

1200 x 2400 |

A1 (Non-combustible) |

|

Glass Wool |

25 - 100 |

50 - 200 |

1200 x 2400 |

A1 (Non-combustible) |

|

Polyvinyl Chloride (PVC) |

20 - 50 |

100 - 300 |

1200 x 2400 |

B2 (Flammable) |

|

Expanded Polystyrene (EPS) |

20 - 100 |

100 - 350 |

1200 x 2400 |

B1 (Flame Retardant) |

What are the advantages of insulation boards?

• Excellent Thermal Insulation:Insulation boards are highly effective at reducing heat transfer, keeping buildings warm in winter and cool in summer. This helps maintain consistent internal temperatures and improves energy efficiency by reducing the need for heating or cooling systems.

• Energy Savings:By improving thermal resistance, insulation boards reduce energy consumption, leading to lower electricity or gas bills. In both residential and commercial buildings, energy savings can be significant over time, making insulation a cost-effective solution.

• Sound Insulation:Many types of insulation boards, particularly those made from rock wool, glass wool, or other fibrous materials, also provide excellent soundproofing. This makes them ideal for reducing noise transmission between rooms, from the outside, or between floors in multi-story buildings.

• Lightweight and Easy to Handle:Insulation boards are generally lightweight, making them easier and safer to handle during installation. This reduces labor costs and makes installation faster and more efficient.

• Moisture Resistance:Insulation boards like extruded polystyrene (XPS) or closed-cell polyurethane (PUR) are resistant to moisture absorption, which helps prevent mold and mildew growth. This is particularly important in areas with high humidity, such as basements, roofs, or exterior walls.

• Durability and Long Lifespan:Insulation boards are designed to be durable and can last for many years without degrading or losing their performance. This makes them a long-term investment for buildings and industrial applications.

• Fire Resistance:Many insulation boards are designed with fire-resistant properties. Materials such as rock wool or mineral wool are non-combustible, while other types like polystyrene may be treated with flame-retardant chemicals to enhance their fire safety performance.

What materials are insulation boards made of?

|

Polystyrene (EPS/XPS) |

EPS is usually light and low-cost, suitable for wall and floor insulation; XPS has better moisture resistance and high compressive strength, and is often used in places such as basements, roofs and floors that require moisture resistance and high-strength support. |

|

Polyurethane (PUR |

Polyurethane insulation board has a very low thermal conductivity, so it provides excellent thermal insulation. It is often used in buildings, refrigeration equipment, etc. that require high thermal insulation performance. |

|

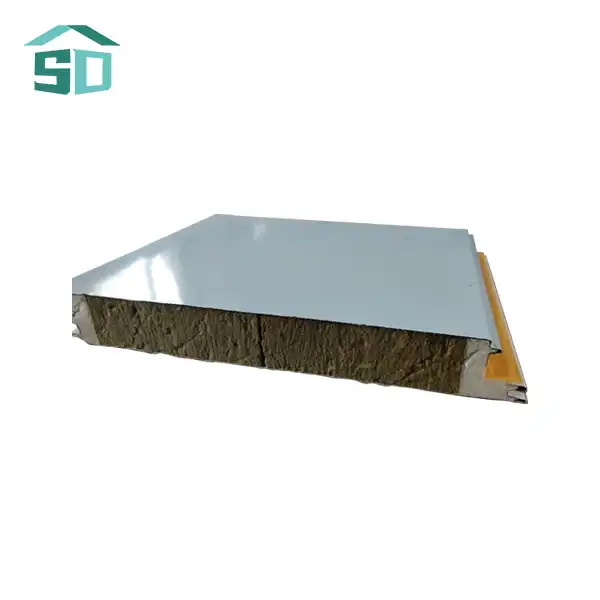

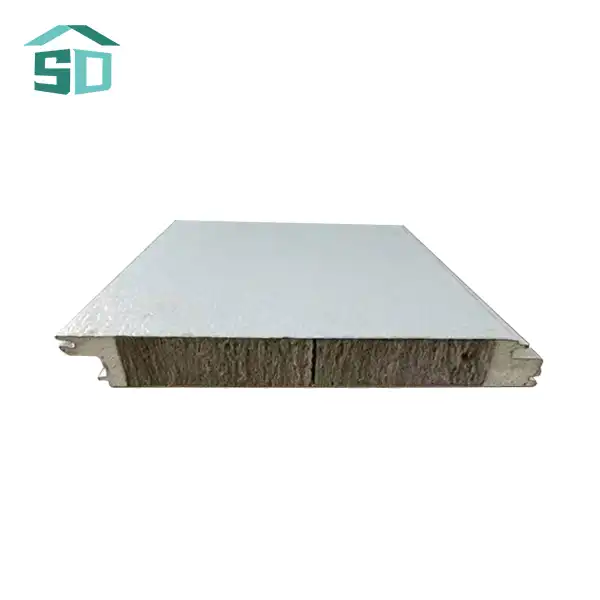

Rock Wool |

Rock wool is made of natural rocks (such as basalt) and has excellent fire resistance and high temperature resistance. In addition to thermal insulation, rock wool also has good sound insulation effect and is widely used in fire insulation, industrial equipment insulation and other fields. |

|

Glass Wool |

Glass wool is made of molten glass and is commonly used for insulation of walls, roofs and air conditioning ducts. It has good thermal insulation and sound insulation effects, and has good fire resistance. |

|

Cork |

Cork is a natural insulation material with good thermal insulation and sound insulation effects. It is an environmentally friendly material and is often used in green buildings, especially suitable for insulation of floors, walls and roofs. |

What are the functions of insulation boards?

l Thermal insulation: The main function of the insulation board is to reduce heat conduction and keep the indoor temperature stable, thereby reducing energy consumption and improving the energy efficiency of the building.

l Fireproof function: Some insulation boards such as rock wool and glass wool have fireproof properties, which can effectively prevent the spread of fire and protect the safety of buildings and personnel.

l Sound insulation and noise reduction: Insulation boards (such as rock wool, glass wool, etc.) also have sound insulation effects and reduce noise transmission. They are particularly suitable for places that require a quiet environment, such as residential buildings, office buildings and industrial plants.

l Moisture-proof and waterproof: Insulation boards such as XPS and PUR have strong moisture-proof and waterproof functions. They are suitable for use in places with heavy humidity such as basements, exterior walls and roofs, effectively preventing moisture from damaging the building structure.

l Improve building durability: Insulation boards help improve the overall durability of buildings and extend their service life by reducing the effects of thermal expansion and contraction.

l Energy saving and emission reduction: By optimizing the energy use of buildings and reducing the need for heating and air conditioning, insulation boards help reduce building energy consumption, achieve energy saving and reduce carbon emissions.

What are the design features of insulation boards?

|

High thermal insulation performance |

The main design feature of the insulation board is its excellent thermal insulation performance. By choosing the right materials (such as XPS, EPS, polyurethane, etc.), the insulation board can effectively reduce heat conduction and keep the internal temperature of the building stable, thereby reducing energy consumption and improving the energy efficiency of the building. |

|

Lightweight and easy to install |

Most insulation boards are designed to be lightweight, easy to cut and easy to install, which makes it convenient for construction workers to complete the installation work quickly and efficiently. |

|

Moisture-proof and waterproof function |

Many insulation board materials (such as XPS, PUR, PIR, etc.) have strong moisture-proof and waterproof properties. The design usually adopts a closed-cell structure to prevent moisture penetration, avoid mold growth or material performance degradation, and is particularly suitable for humid environments such as basements and exterior walls. |

|

Fireproof design |

Materials such as rock wool and glass wool have natural fire-resistant properties, while some polystyrene materials (such as XPS, EPS) will be specially flame-retardantly treated to ensure their safety in fires. |

|

Excellent durability and stability |

Insulation boards are usually designed to be resistant to aging, pressure and high temperature to ensure that they maintain good insulation effects for a long time. Durability and stability of materials are key to long-term use of buildings, especially in extreme climate conditions. |

|

Environmental protection and sustainability |

Use of recyclable materials (such as cork, glass wool, etc.) or low environmental impact manufacturing processes aims to reduce the carbon footprint of building materials. Some types of insulation boards are also biodegradable, meeting the requirements of green buildings. |

FAQ

Q1: What are the main uses of insulation boards?

A1: Insulation boards are mainly used in many fields such as construction, refrigeration, electrical appliances, and pipelines to provide functions such as heat insulation, thermal insulation, fire protection, and energy saving.

Q2: How do I choose the appropriate thickness of insulation boards?

A2: The thickness of the insulation board depends mainly on its application environment and needs. For example, for occasions that require high thermal insulation and heat insulation, you may need to choose a thicker insulation board.

Q3: What materials are available for insulation boards?

A3: Insulation boards are made of a variety of materials, such as rock wool, glass wool, polystyrene foam (EPS, XPS), polyurethane foam, etc. Each material has its own unique properties and uses, and you can choose according to your needs.

Q4: What is the fire resistance of insulation boards?

A4: Insulation boards of different materials have different fire resistance levels. When purchasing, be sure to understand the fire resistance level of the product to ensure that it meets your safety needs.

Q5: Is the insulation board environmentally friendly?

A5: Most modern insulation board products meet environmental protection requirements, but it depends on the material and production process of the product.

Q6: How to install insulation board?

A6: The installation method of insulation board varies depending on the material and application environment. Generally speaking, you need to prepare the necessary tools and materials, such as knives, adhesives, fixings, etc., and install them according to the product instructions or professional guidance.

Q7: What is the service life of insulation board?

A7: The service life of insulation board depends on many factors, such as material, use environment, installation method, etc. Generally speaking, the service life of high-quality insulation board can be up to decades. In order to ensure its long-term performance, it is recommended that you conduct regular inspections and maintenance.