PU sandwich panels have gotten to be progressively well known in the development industry due to their extraordinary cover properties, solidness, and flexibility. As a driving supplier of outside cladding and veneer arrangements, Weifang Sandong Building Materials Co., Ltd. is here to address a few of the most regularly inquired questions almost PU sandwich panels. Whether you're a prepared designer, an inquisitive builder, or a property proprietor looking to update your building's cover, this comprehensive direct will give you with profitable experiences into the world of PU sandwich panels.

Understanding the Basics of PU Sandwich Panels

PU sandwich panels, too known as polyurethane sandwich panels, are composite materials comprising of two metal facings with a polyurethane froth center. These panels are eminent for their predominant warm separator properties, making them an great choice for different development applications. One of the most common questions we receive is, "What exactly are PU sandwich panels made of?" The answer lies in their three-layer construction. The outer layers typically consist of metal sheets, such as steel or aluminum, while the core is made of rigid polyurethane foam. This unique combination results in a lightweight yet sturdy panel that offers exceptional thermal and acoustic insulation.

Another visit request is approximately the thickness of PU sandwich panels. The thickness can change depending on the particular prerequisites of a extend, but by and large ranges from 25mm to 200mm. The choice of thickness depends on components such as the wanted level of cover, auxiliary necessities, and neighborhood building codes. Many clients also ask about the lifespan of PU sandwich panels. When properly installed and maintained, these panels can last for several decades. Their durability is one of the key reasons why they're favored in both commercial and residential construction projects.

Applications and Benefits of PU Sandwich Panels

A question that often arises is, "Where can PU sandwich panels be used?" The versatility of these panels allows for a wide range of applications. They're commonly used in:

- Cold storage facilities

- Industrial buildings

- Commercial structures

- Residential constructions

- Agricultural buildings

- Modular and prefabricated structures

The adaptability of PU sandwich panels is one of their greatest strengths. They can be used for walls, roofs, and even as partition walls in interior spaces. This versatility makes them a favored choice among architects and builders looking for flexible and efficient building solutions.

Another common question is about the benefits of using PU sandwich panels. Some of the key advantages include:

- Excellent thermal insulation

- Lightweight yet durable construction

- Quick and easy installation

- Cost-effective over the long term

- Fire-resistant properties (when treated)

- Soundproofing capabilities

- Resistance to moisture and mold

Many clients are particularly interested in the energy-saving potential of PU sandwich panels. Due to their superior insulation properties, these panels can significantly reduce heating and cooling costs, making them an environmentally friendly and economically beneficial choice for construction projects. A question that often comes up is, "How do PU sandwich panels compare to other insulation materials?" While there are many insulation options available, PU sandwich panels stand out for their combination of high insulation value, structural strength, and ease of installation. Compared to traditional insulation methods, they offer a more comprehensive solution that addresses both insulation and structural needs in one product.

Installation and Maintenance of PU Sandwich Panels

One of the most common questions we receive regarding PU sandwich panels is about the installation process. Many wonder, "Is it difficult to install PU sandwich panels?" The good news is that these panels are designed for relatively easy installation. Their lightweight nature and interlocking design allow for quick assembly, often reducing construction time compared to traditional building methods. Another frequently asked question is about the maintenance requirements of PU sandwich panels. These panels are known for their low maintenance needs, which is another factor contributing to their popularity. Regular cleaning with mild detergent and water is usually sufficient to keep the panels in good condition.

Many clients also inquire about the possibility of painting PU sandwich panels. While the panels come in a variety of colors and finishes, it is possible to paint them if a change in appearance is desired. However, it's crucial to use paint that is compatible with the panel's surface material to ensure proper adhesion and longevity. A common concern is about the fire resistance of PU sandwich panels. It's important to note that while polyurethane foam is combustible, many PU sandwich panels are treated with fire-retardant additives to improve their fire resistance. When choosing panels for your project, be sure to select those that meet the fire safety standards required for your specific application.

Clients often ask about the environmental impact of PU sandwich panels. While the production of polyurethane foam does have some environmental considerations, the long-term energy savings and durability of these panels can offset their initial environmental cost. Additionally, many manufacturers are now focusing on more sustainable production methods and materials to reduce the environmental impact further. Another question that frequently comes up is about the cost-effectiveness of PU sandwich panels. While the initial cost may be higher than some traditional building materials, the long-term benefits often outweigh this. The energy savings, reduced maintenance needs, and longevity of the panels can result in significant cost savings over the life of the building.

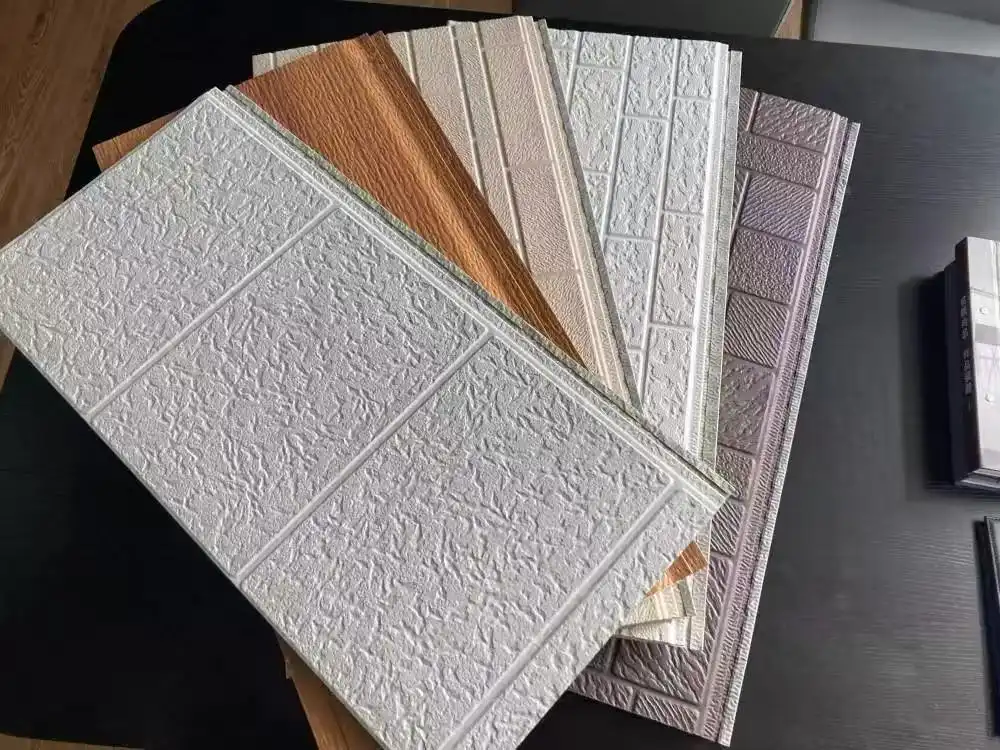

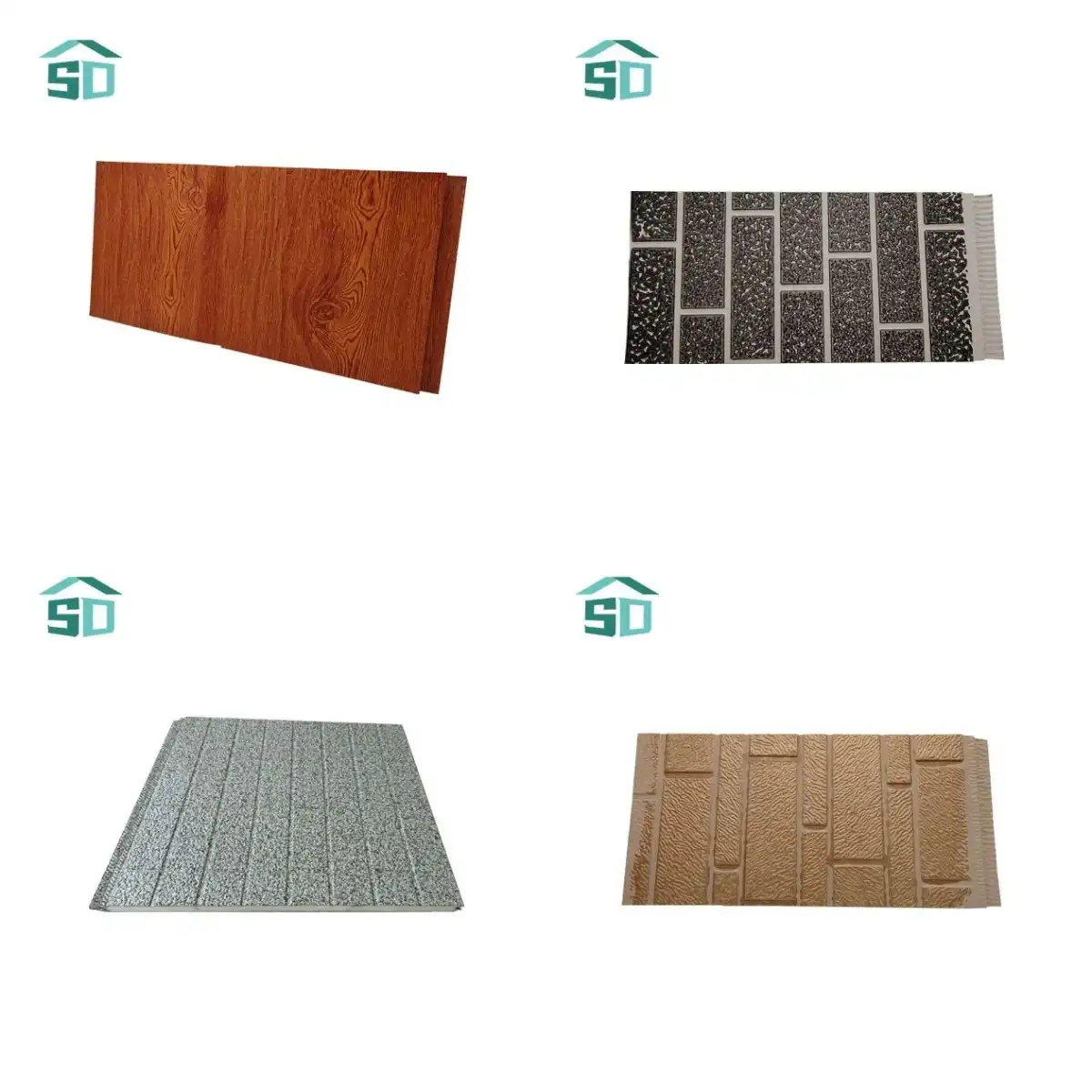

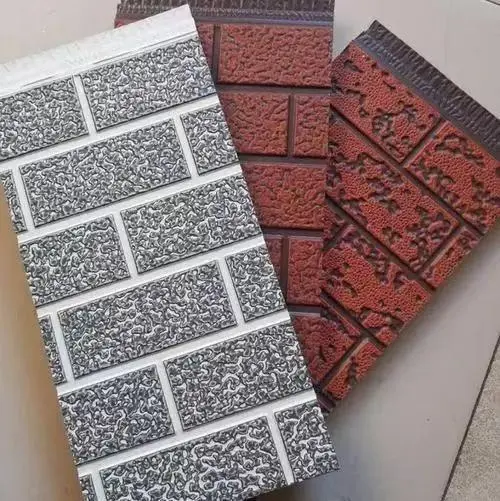

Many people also wonder about the possibility of retrofitting existing buildings with PU sandwich panels. This is indeed possible and can be an effective way to improve the energy efficiency of older structures. However, the feasibility and method of retrofitting will depend on the specific characteristics of the existing building. A question that architects and designers often ask is about the design flexibility of PU sandwich panels. These panels offer considerable design freedom, available in various colors, textures, and profiles. They can be cut to size and shape, allowing for creative architectural expressions while maintaining their functional benefits.

Lastly, a common query is about the warranty on PU sandwich panels. The warranty period can vary depending on the manufacturer and specific product line. At Weifang Sandong Building Materials Co., Ltd., we stand behind the quality of our products and offer competitive warranty terms. It's always advisable to discuss warranty details with your supplier when planning your project.

https://www.youtube.com/watch?v=EFa9XJhv0oE Conclusion

In conclusion, PU sandwich panels offer a multitude of benefits for modern construction projects. Their combination of insulation properties, durability, and ease of installation makes them an attractive option for a wide range of applications. As with any building material, it's crucial to consider your specific project requirements and consult with experts to ensure you're making the best choice for your needs.

If you have more questions about PU sandwich panels or want to explore how they can benefit your next construction project, don't hesitate to reach out to us at info@sdqsc.com. Our team of experts at Weifang Sandong Building Materials Co., Ltd. is always ready to provide you with the information and support you need to make informed decisions about your building materials.

References

1. Polyurethane Foam Association. "What is Polyurethane Foam?" Available at: https://www.pfa.org/what-is-polyurethane-foam/

2. Building and Environment Journal. "Energy and environmental performance of building façades integrated with phase change material in subtropical Hong Kong." Available at: https://www.sciencedirect.com/science/article/abs/pii/S0360132316304152

3. Construction and Building Materials Journal. "Life cycle assessment of polyurethane-faced sandwich panels: Improvement opportunities." Available at: https://www.sciencedirect.com/science/article/abs/pii/S0950061818301107

4. Energy and Buildings Journal. "Thermal performance of insulated metal panel systems as alternative wall assemblies for building envelopes." Available at: https://www.sciencedirect.com/science/article/abs/pii/S0378778816302201

5. International Journal of Engineering Research and Applications. "A Review on Sandwich Composite and Sandwich Composite with Polymer Foams." Available at: https://www.ijera.com/papers/Vol4_issue3/Version%201/B43010110.pdf

The Aesthetic Appeal of Decorative Wall Panels

The Aesthetic Appeal of Decorative Wall Panels

Textured Finishes and Patterns

Textured Finishes and Patterns

By following these maintenance guidelines, you can extend the life of your decorative exterior wall panels and keep them looking as impressive as the day they were installed.

By following these maintenance guidelines, you can extend the life of your decorative exterior wall panels and keep them looking as impressive as the day they were installed.

It's worth noting that reputable manufacturers like Weifang Sandong Building Materials Co., Ltd. offer comprehensive product information and expert guidance to help you make an informed decision. Their commitment to quality is evident in their rigorous testing procedures, which cover everything from the thickness and mechanical strength of the panels to their flame retardancy and overall appearance.

It's worth noting that reputable manufacturers like Weifang Sandong Building Materials Co., Ltd. offer comprehensive product information and expert guidance to help you make an informed decision. Their commitment to quality is evident in their rigorous testing procedures, which cover everything from the thickness and mechanical strength of the panels to their flame retardancy and overall appearance.