- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

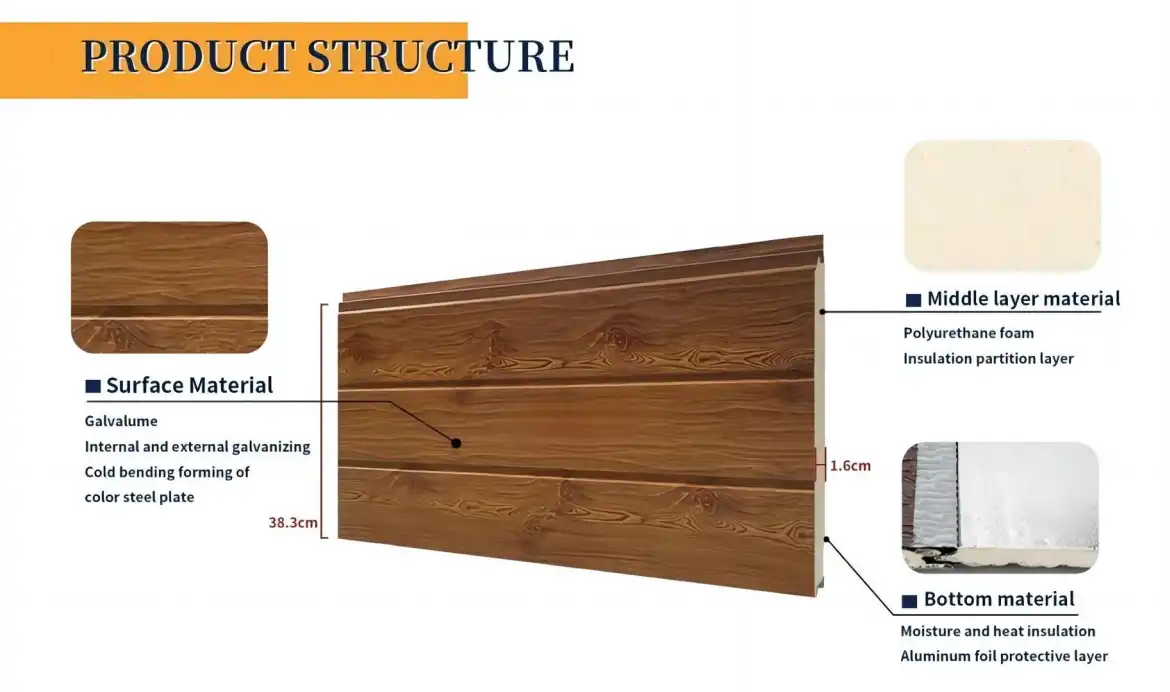

Insulated Sandwich Wall Panels

Superior Insulation for Energy-Efficient Insulated Sandwich Wall Panels

Thermal Barrier: Heat Retention & Insulation for All Seasons

Fire-Resistant Insulated Panels: Safety First in Wall Construction

Corrosion-Proof Design: Ensuring Durability in Harsh Environments

Customizable Colors & Patterns for Insulated Wall Panels

Easy-to-Install Insulated Sandwich Panels for Rapid Construction

Eco-Friendly Insulation: Green Building Material Choice

Cost-Effective Solution for High-Performance Wall Systems

Quality, Durability & Versatility in Insulated Sandwich Wall Panels

Insulated Sandwich Wall Panels Introduction

Welcome to our comprehensive guide on Insulated Sandwich Wall Panels! These innovative building materials are designed to enhance energy efficiency, durability, and aesthetic appeal in various construction applications. Our panels are perfect for both new constructions and renovations, offering excellent thermal insulation, soundproofing, and fire resistance. With over 30 years of experience serving clients worldwide, Weifang Sandong Building Materials Co., Ltd. is your trusted partner for high-quality cladding solutions.

Product Specifications

|

Length |

Customized |

|

Thickness |

(Interior 10mm) (Exterior 16mm/20mm) |

|

Width |

(Exterior 383mm) (Interior 450mm) |

|

Thickness of surface materials |

0.23mm,0.25mm,0.27mm |

|

Fire-protection rating |

B1/B2 |

|

Waterproof Rate |

0.0008 |

|

Wind Resistance |

8.0 Kpa |

|

Thermal Conductivity |

0.018W/m.k |

|

Thermal Resistance |

2.09m2k/w |

|

Compressive Strength |

52.7kpa |

Product Advantages

Energy Efficiency: Our insulated panels significantly reduce energy consumption by providing exceptional thermal insulation, helping to lower heating and cooling costs.

Durability: Constructed from high-quality materials, these panels are built to withstand harsh weather conditions and resist corrosion.

Aesthetic Versatility: Available in a wide range of colors and finishes, our panels enhance the visual appeal of any building.

Easy Installation: Designed for quick and efficient installation, reducing labor costs and project timelines.

Sustainability: Made from recyclable materials, our panels contribute to environmentally friendly construction practices.

Technical Features

Fire Resistance: Our panels meet stringent fire safety standards, ensuring peace of mind for residential and commercial projects.

Soundproofing: The advanced insulation materials used in our panels provide excellent sound attenuation, creating a quieter indoor environment.

Customization: Tailor-made solutions to meet specific project requirements, including size, thickness, and material selection.

Product Installation

Installing it is straightforward and efficient. Follow these steps:

Preparation: Ensure the surface is clean, dry, and free from debris.

Layout: Plan the panel arrangement according to the building design.

Fastening: Use appropriate fasteners to secure the panels in place, ensuring a tight fit.

Sealing: Apply sealants where necessary to prevent air and water ingress.

Finishing: Complete the installation with any desired surface treatments or finishes.

Product Accessories

To enhance the functionality and performance of our Insulated Sandwich Wall Panels, consider these accessories:

Sealants and Adhesives: For securing and sealing joints.

Insulation Inserts: For additional thermal performance.

Edge Trims: To provide a polished finish and additional protection against moisture.

Product Application

Our Insulated Sandwich Wall Panels are ideal for a variety of applications, including:

Construction Industry: Used for exterior walls, roofs, and interior wall cladding.

Industrial Applications: Perfect for thermal insulation in manufacturing plants, warehouses, and cold storage facilities.

Transportation: Suitable for interior and exterior decoration of vehicles, ships, and aircraft.

OEM Service

We offer comprehensive OEM services tailored to meet your specific project needs. From custom sizes and materials to unique color finishes, our dedicated team works closely with you to deliver personalized solutions.

FAQ

1. What are they made of?

Our panels are made from a combination of metal materials such as aluminum, steel, or stainless steel, with various insulation layers like polyurethane or polystyrene.

2. Can I get a sample before placing an order?

Yes, we provide samples upon request to help you evaluate our product quality and suitability for your project.

3. What certifications do your panels meet?

Ours comply with international quality standards, including ISO, CE, and UL certifications.

4. How do I ensure proper installation?

We offer technical support and installation guidance to ensure that our panels are installed correctly for optimal performance.

Contact Us

Ready to enhance your construction project with our Insulated Sandwich Wall Panels? For more information, customization options, or to request a quote, please contact us at info@sdqsc.com. Our team is here to assist you!