- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

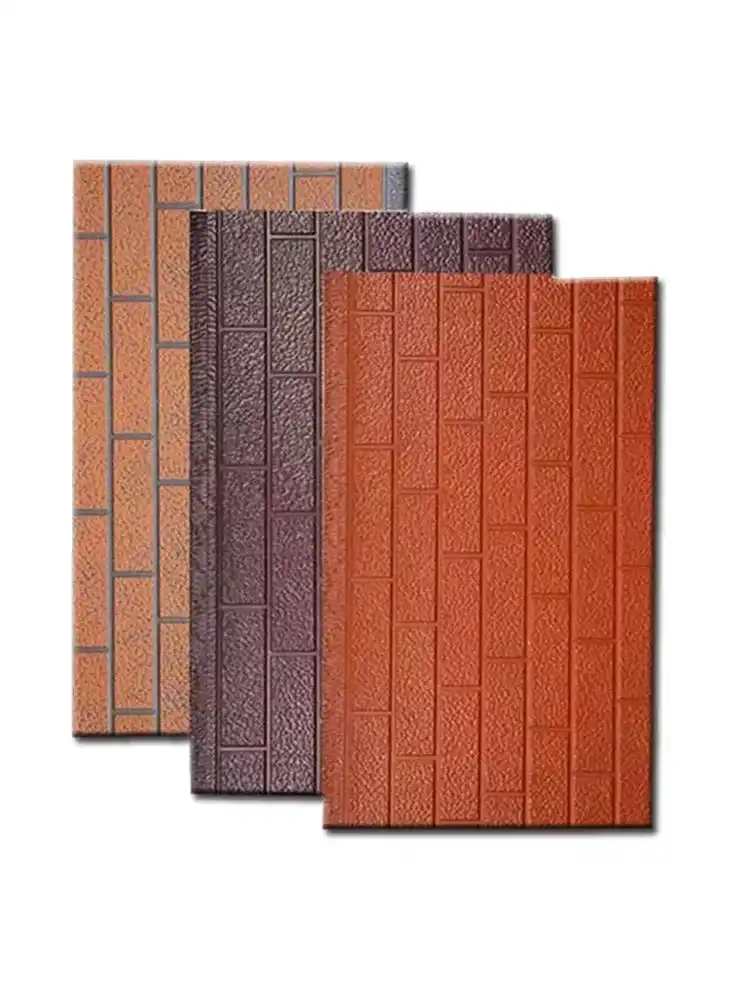

Foam Exterior Wall Cladding

Parameter: Exceptional Insulation & Thermal Efficiency

Advantage: Flame-Retardant Foam Cladding for Safety

Selling Point: Fully Customizable Colors & Patterns to Enhance Aesthetics

Corrosion-Resistant Foam for Long-Lasting Protection

Product Highlight: Energy-Saving Insulation for Sustainable Buildings

Foam Cladding: Versatile Solution for Both Functional & Decorative Needs

Tailor-Made Foam Wall Cladding - Matching Your Project's Vision

Eco-Conscious Choice:

Durable & Environmentally Friendly Foam Cladding

Easy Installation & Maintenance: Top Reasons to Choose Foam Exterior Wall Cladding

Foam Exterior Wall Cladding Introduction

Welcome to our Foam Exterior Wall Cladding page, where innovation meets durability. Designed to enhance the aesthetic appeal and energy efficiency of your building, our foam cladding solutions are perfect for both new constructions and renovations. With a variety of customization options available, our product is ideal for projects seeking both functionality and style. Whether you are a contractor, architect, or business owner, our products are tailored to meet your specific needs.

Product Specifications

|

Length |

Customized |

|

Thickness |

(Interior 10mm) (Exterior 16mm/20mm) |

|

Width |

(Exterior 383mm) (Interior 450mm) |

|

Thickness of surface materials |

0.23mm,0.25mm,0.27mm |

|

Fire-protection rating |

B1/B2 |

|

Waterproof Rate |

0.0008 |

|

Wind Resistance |

8.0 Kpa |

|

Thermal Conductivity |

0.018W/m.k |

|

Thermal Resistance |

2.09m2k/w |

|

Compressive Strength |

52.7kpa |

Product Advantages

Excellent Insulation: Our product provides superior thermal and acoustic insulation, ensuring comfort in any environment.

Lightweight and Easy to Install: The lightweight nature of foam cladding reduces installation time and labor costs.

Aesthetic Versatility: Available in a wide range of colors and finishes, our cladding can complement any architectural style.

Durability: Resistant to moisture, rot, and corrosion, our foam cladding is built to last in diverse weather conditions.

Sustainable: Made from environmentally friendly materials, our cladding supports green building initiatives.

Technical Features

High R-value: Offers excellent energy efficiency, reducing heating and cooling costs.

Impact Resistance: Designed to withstand harsh conditions and impact, maintaining integrity over time.

UV Stability: The cladding is treated to resist UV rays, preventing fading and degradation.

Fire Resistance: Manufactured to meet stringent fire safety standards, ensuring peace of mind.

Product Installation

Installing our Foam Exterior Wall Cladding is a straightforward process. Follow these steps for optimal results:

Prepare the Surface: Ensure the wall surface is clean, dry, and free from any debris.

Cut the Panels: Use a saw to cut panels to the desired size, ensuring precise measurements.

Apply Adhesive: Use a suitable adhesive to attach the panels to the wall, following manufacturer guidelines.

Secure Panels: Fasten panels using screws or mechanical fasteners for added stability.

Finish: Seal any joints with appropriate sealants to enhance insulation and aesthetics.

Product Accessories

Edge Trims: For a polished finish on edges.

Sealants: To ensure airtight installation and prevent moisture ingress.

Fastening Systems: Specialized screws and brackets for secure panel attachment.

Foam Exterior Wall Cladding Application

Foam exterior wall cladding is versatile and suitable for various applications:

Residential Buildings: Enhances curb appeal and energy efficiency.

Commercial Spaces: Provides a professional and modern look.

Industrial Facilities: Ideal for thermal insulation and soundproofing.

Transportation: Used in vehicles and vessels for insulation and aesthetic purposes.

OEM Service

We offer OEM services to customize our product according to your specific project requirements. From dimensions and colors to materials and finishes, we can help you create a product that perfectly suits your needs.

FAQ

1. What is the lead time for bulk orders?

Lead time typically ranges from 4 to 6 weeks, depending on the order size and customization.

2. Can I request a sample before placing a bulk order?

Absolutely! We encourage potential customers to request samples for evaluation.

3. Is the foam cladding environmentally friendly?

Yes, our Foam Exterior Wall Cladding is made from recyclable materials and designed to meet sustainability standards.

4. How do I clean the cladding?

Cleaning is simple; just use a mild detergent and water with a soft cloth to maintain its appearance.

Contact Us

For more information about our Foam Exterior Wall Cladding or to request a quote, please reach out to us at [info@sdqsc.com]. Our dedicated team is here to assist you with any inquiries you may have.